PFA/PTFE-lined Hermetic Magnetic Drive Pump For Conveying Large Volumes of Highly Corrosive Media. Lined pumps are an economical alternative to metallic magnetic drive pumps for a whole series of applications, as the following example from real life shows.

Wacker Chemie operates alone in the Burghausen/Germany works some 16,000 continuous-flow machines, including about 750 lined Richter pumps. At the Business Unit “Acetyls”, in Burghausen/Germany a PFA/PTFE lined magnetic drive pump—the MNK 200-150-315—has been undergoing a practical test since December 2007, conveying a very corrosive mixture consisting of acetic acid, formic acid and acetaldehyde at temperatures of up to 80 °C. It is operating there in an area of the plant which is regarded as particularly difficult.

of up to 60 m LC.

The trial operations lasting several months are to provide the proof that a considerably longer service life is possible compared with the metallic magnetic drive and mechanical seal pumps previously tested and used. Background: Metallic pumps have problems with crevice corrosion when conveying acetic acid at elevated temperatures, the pumps had to be serviced and repaired at intervals of six to twelve months.

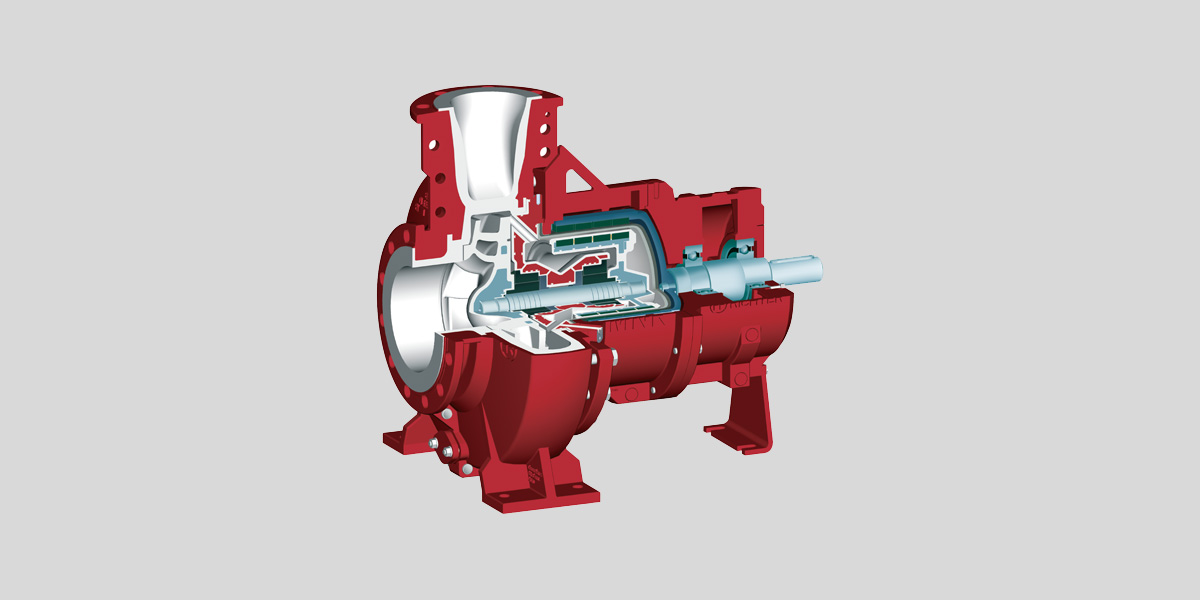

The conditions for a long service life are good: The MNK 200-150-315 is designed as a single- stage, sealless chemical centrifugal pump of heavy-duty, horizontal design in accordance with EN 22858/ISO 2858/ISO 5199 and therefore qualified, for example for chlorine electrolysis and sulphuric acid production and recovery. It can be used for flow rates of up to 600 m³/h at delivery heads of up to 60 m LC. The pump is rated for operating pressures of up to PN 25. The admissible operating temperatures are between–60 °C and +150 °C with the potential to be increased.

A special plain bearing system prevents damage

All components which come into contact with the medium either have a thick PFA and PTFE fluoroplastic lining (housing, impeller, plain bearing pedestal, shaft and inner magnet assembly), are made of solid PTFE fluoroplastic (can insert) or made of sintered silicon carbide SSiC (plain bearings). The “Safeglide Plus” plain bearing system prevents damage in the event of brief dry-running. The double can system between the inner and outer magnet assemblies ensures freedom from leaks: The fluoroplastic can insert is highly resistant to corrosion, the outer can made of carbon-fibre composite material bears the pressure load.

High-performance permanent magnets are rated for torques of up to 800 Nm and transmit 120 kW at 1450 rpm and 165 kW at 2000 rpm respectively.

Conclusion: The pump has been operating without any problems since it was installed in December 2007. If the pump proves successful, the operator is expecting very significant LCC savings of up to 70 per cent. The MNK is a recognised alternative to magnetic drive pumps made of special metals such as Hastelloy, Alloy20, silicon cast iron, tantalum, nickel etc. It is cheaper to procure, generates no expensive eddy-current losses and the delivery time for the pump and spare parts can be estimated at only four to eight weeks instead often to over 20 weeks.

Ten more MNK 200-150-315 have already been or will be put into operation this year at various international chemical companies—with flow rates of up to 400 m³/h, also for conveying HCl and H2SO4 at temperatures of up to more than 150 °C.